Nissan hopes its solid-state electric vehicle batteries won’t require cooling at all

Nissan is one of several automakers looking at solid-state battery technology as a potential game-changer for electric vehicles in the next decade. Internally, the company plans to both perfect the development of all-solid-state battery cells (ASSB) and specify their manufacturing, with the technology to be implemented into a series electric vehicle by 2028.

If all goes well, Nissan would like to use the technology for other types of vehicles – esp SUVs, pickups and vans– make sense in fully electric form by the end of the decade.

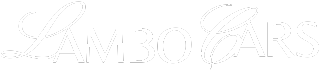

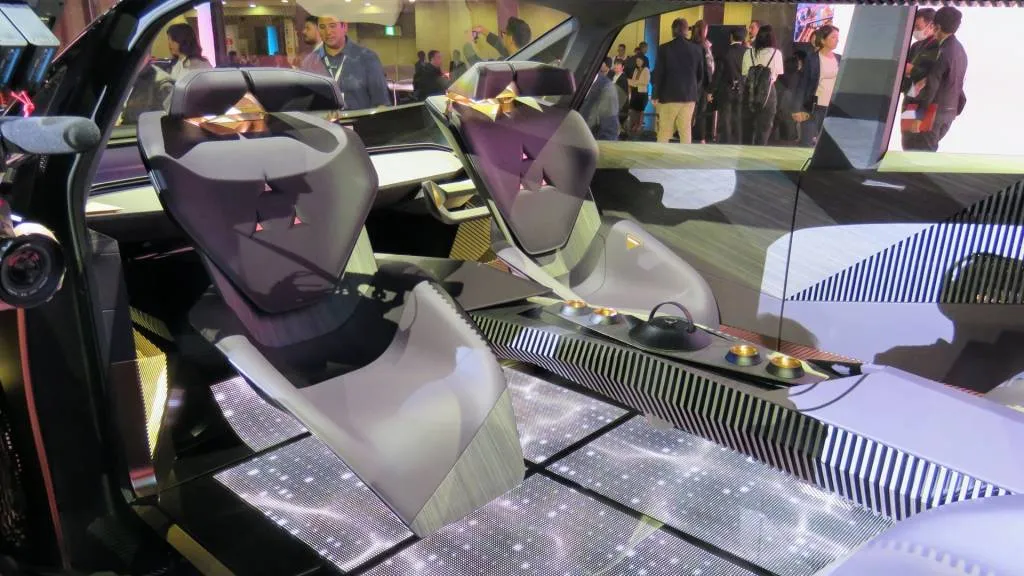

That seemed to be the core of it Hypertourer concept Nissan introduced a very thin, flat under-floor solid-state battery pack at the Tokyo auto show last week that enables long-distance driving without compromising on packaging.

Nissan Hyper Tourer concept

Nissan Hyper Tourer concept

Nissan Hyper Tourer concept

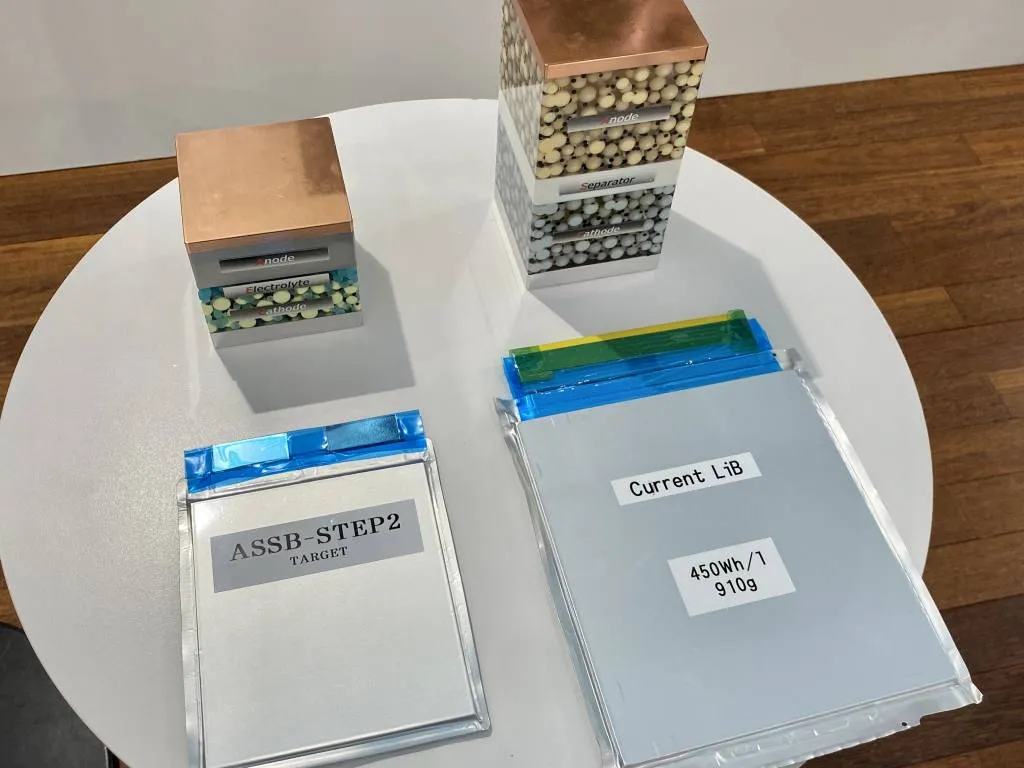

Compared to current lithium-ion cell technology in electric vehicles, Nissan aims to effectively double energy density at the pack level while reducing fast charging time by two-thirds.

At the same time, lithium-ion technologies and other battery types are developing and improving. In a roundtable interview last week at the Tokyo auto show, Nissan’s global research and development chief Kazuhiro Doi told Green Car Reports that solid-state cell technology could represent more than just an incremental improvement over lithium-ion batteries.

In order to achieve these goals, Doi emphasized, ideally all cooling would have to be avoided.

Solid-state runs hot and that’s okay

“In the case of ASSB, perhaps we can do without cooling,” he said, stressing that the final design has not yet been decided but the aim is to avoid it altogether.

As Doi acknowledged to some raised eyebrows and confirmed to Green Car Reports, that means no water cooling, no forced air cooling, and not even any passive cooling – certainly different than what some automakers have suggested.

2011 Nissan Leaf – Battery Pack in Section

It’s a somewhat loaded topic. Nissan underestimated the cooling needs of the Nissan Leaf’s original battery cells, which degraded quickly in hot climates when parked on a hot asphalt surface or quickly charged too often. A subsequent one Battery chemistry change in 2015 helped solve that, and ever since Blade battery deterioration was much better.

One goal of the development engineers was to eliminate the bulky water cooling system in other modern electric vehicles. Mercedes thought about air cooling In its most recent EQXX concept, the company announced a new generation of electric vehicles – still with lithium-ion cells – and ultimately decided against it.

But Nissan already has more hands-on experience with the technology, and the reason for skipping cooling on ASSB is simple: it’s okay for them to get much hotter than what’s considered normal for other EV batteries, and The cells have a wide range of temperature sweet spots – from room temperature up to 100 degrees C or 212 degrees F.

To maintain the advantage over lithium-ion technologies and make the entire development worthwhile, Nissan must have a superior product that does not rely on cooling by then, Doi reiterated.

For most lithium-ion cells, the temperature threshold is around 60°C or 140°F, and fast charge times are limited to prevent cell temperatures from approaching this temperature. Without having to worry so much about temperature, Nissan’s solid-state cells could be charged to nearly 100% in about 15 minutes.

Nissan Surf-Out, Max-Out and Hang-Out concepts

Nissan expects solid-state vehicles to be the first to make it big

Solid State could be applicable to all types of vehicles. While some companies – Toyota, for example – have hinted that they are solid-state cells could first appear in hybrids. Nissan believes it makes more sense to focus on solid-state vehicles first for one model type: large, long-range, all-electric vehicles.

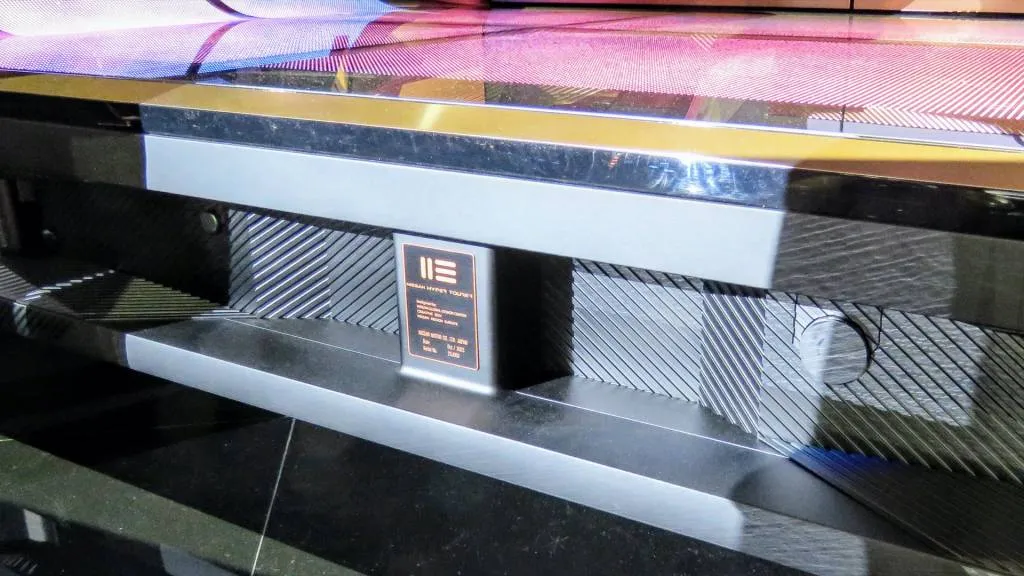

Doi explained that trucks, vans and SUVs require a lot more energy, “but if we use that today with lithium-ion battery technology, the size is huge.” Taking the cooling system out of the equation would make it a smaller one Space requirements and much less complexity of the battery pack would result in space for more spacious vehicles – or possibly for more range and less mass.

2022 GMC Hummer EV

Juggling performance, safety and durability

This time, Nissan needs to get the battery composition right from the start, and there are still longevity hurdles to resolve. In a laboratory situation with enlarged test cells, around 200 cycles are observed – not nearly enough for a series electric vehicle.

After initially working with single-layer cells with a diameter of just 2 cm in the laboratory, Nissan still plans to set up a pilot line for cells with a diameter of about 10 cm in 2024. The actual production cell will be “much larger,” Doi said. Nissan plans to produce larger-sized cells in the pilot plant as it seeks to determine the size of the plant that might be needed to increase production.

As Doi previously said, Nissan incorporates its own nail penetration tests and X-rays into its studies of the solid-state cells, which undergo rigorous safety and durability testing. There have been no incidents of fire or thermal runaway with the Nissan Leaf, and the same safety priorities apply when building these new cells.

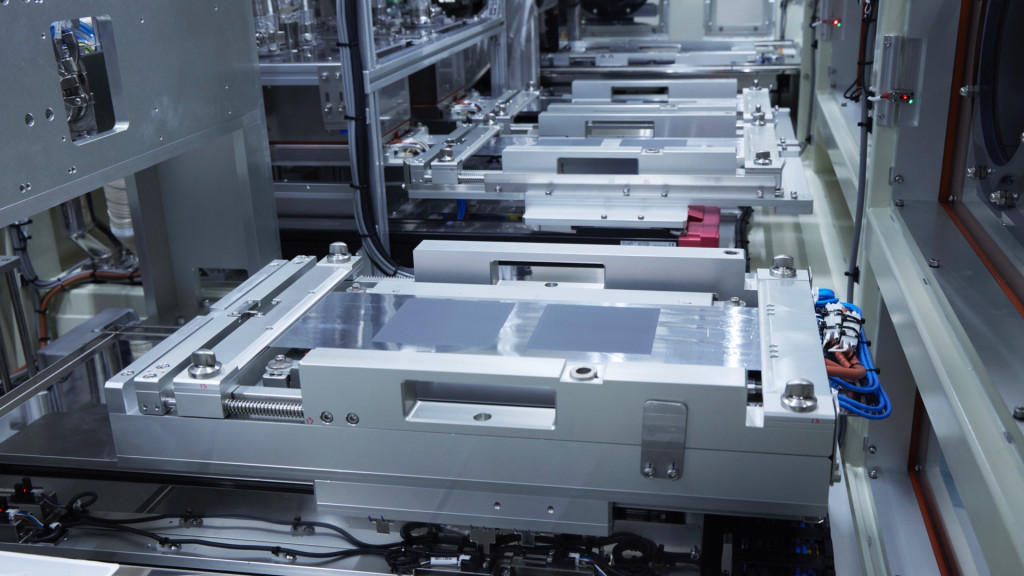

Production of Nissan solid-state battery prototypes

Nissan’s solid-state technology benefits from a partnership with NASA and UC San Diego, where AI techniques helped select the best interlayer to prevent the growth of lithium dendrites that could eventually break through and short out the cells. The electrolyte with high ionic conductivity was chosen because of its stability, the anode because of its high power potential.

However, the fine-tuning of the cells is not yet complete and we cannot yet provide exact specifications for them. Cell performance is determined not only by chemistry, but also by the cathode and anode layers, Doi explained. A thicker cathode results in higher energy density, but also negatively impacts charging rates. “First we have to get the chemistry right, and once we get the chemistry right, we can estimate the power per cell,” he said.

Nissan ASSB vs. lithium-ion

Further development of solid-state technology

Doi also emphasized that there will be a major development in chemistry. The addition of nickel for energy density and range in lithium-ion cells is one example, he said, and the same will happen with solid-state cells.

Apart from ASSB, high in manganese and Sulfur based chemicals are the next best hope, says Doi. “Then we can also use this for small cars – I think the potential is very attractive,” he said.

Nissan is targeting solid-state cell costs as low as $75 per kWh, which could put them on par with lithium-ion cells by the end of the decade. If ASSB can be used for larger vehicles, the optimal solution for smaller EVs could be a combination of these chemistries with solid-state solutions – an even cheaper, less resource-intensive solution without the lifecycle challenges. However, the cooling for such a combination still needs to be determined.